Coffee roasting, similar to cooking, is a skillful process that requires a degree of artistry to make successful. It involves monitoring the roasting temperature and level of development of the coffee beans throughout the roasting process, manipulating the timings and temperatures and reacting to any changes throughout the roast. Only through experience and experimentation can a master roaster correctly obtain the desired characteristics in the finished product.

There are several stages in the coffee roasting process, however, we will take you through the dark roast today, which reaches all the stages.

Firstly, Luigi or the master roaster of the day, preheats the coffee roaster to the temperature according to the batch size (kg of green coffee beans), and the origin coffee. These temperatures have been carefully amended over time as we want to avoid scorching (burn marks from the hot roasting drum on the coffee bean). We have a gas roaster and you can see the gas burners under the roasting drum. You can control the flame intensity throughout the coffee roasting stage (as you would with cooking on the stove).

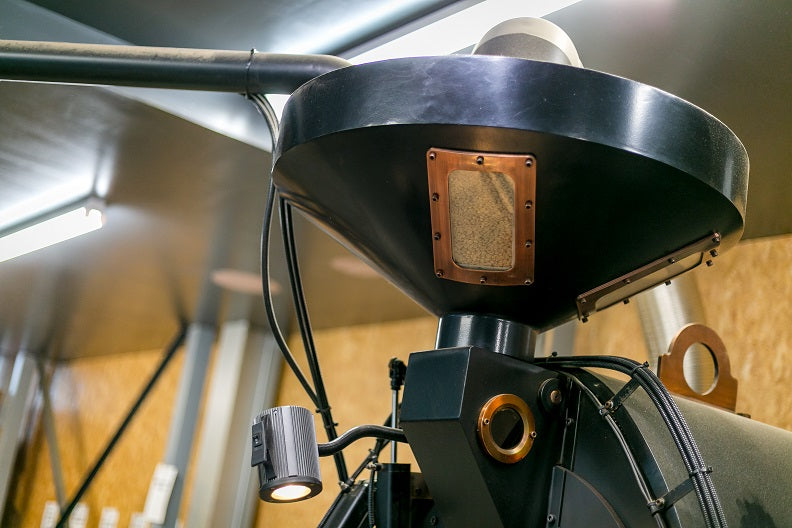

Luigi then weights 30kg of green unroasted coffee beans and pours them into the loading bucket. The beans we are going to roast are one of our best selling coffee beans - Colombia Huila. On this particular roaster, the beans get sucked out into the hopper on the top of the coffee roaster by pressing a button.

Once the heated rotating drum reached 180C - 190C, the green coffee beans are dropped into the roasting drum and the first stage in the roasting process begins. The drum temperature drops because of the cold coffee beans down to about 50 - 60C. The temperature then starts rising after about 2 min.

At this point, you the roast smells straw-like, or grassy smell. It is quite intense smell, but the roasters are used to it and they can recognise the stage of the roast easily even without looking at the colour of the beans or the software on the screen.

As the roast progresses, the temperature begins to rise. The coffee beans start to swell as the heat breaks down their cell walls and you can hear a popping sound or "first crack". This is also called the "Maillard stage" of the roast, where the beans are out of the drying stage and into the cooking stage.

The coffee beans continue to expand and, as the roast progresses and the heat intensity rises, they begin to release oils and caramelise the sugars further, creating a deep, rich flavour. We now begin to hear the "second crack", which is a more distinct, sharp sound than the first crack. This is a very important stage of the roast, the colour is very closely monitored as every second matters. Once Luigi is happy with the colour, he drops the beans into the cooling tray by pressing a button on the control panel.

One of the bi-products produced from roasting coffee beans is known as 'chaff'. This is a layer that surrounds the seed of the coffee cherry, which is shed as the beans heat up. Chaff is beneficial to the environment as it contains lots of nitrogen and its caffeine content can help to deter pests.

If you are interested in coffee roasting at home, check out our selection of Green Coffee Beans.

2 comments

Hi David, Yes, Luigi is indeed a great roaster. We take Colombia Excelso Huila to an extra dark roast, extending it beyond the second crack. However, it’s a fine balance—while this process can enhance rich, chocolatey notes, it also poses the risk of overshadowing other origin flavours and veering into burnt territory.

This is fascinating! Thanks for the detailed explanation of the dark roast process. It sounds like Luigi is a true master roaster – the ability to identify stages based on smell alone is impressive. Have you ever experimented with extending the roast time after the second crack? I hear it can bring out even more chocolatey notes in certain beans.